The world of wood preservation is based on innovative chemistry. Companies rarely get the opportunity to share the laboratory work that forms the majority of any Biocidal Products Regulation (BPR) efficacy package because the focus in industry press tends to be on the treated wood. In this article, Dr Stephen Uphill, Arxada’s technical lead for wood protection, provides a taste of what is scientifically involved in the development of a biocidal product for use as a wood preservative (PT 8).

ASSESSMENT OF ACTIVE INGREDIENTS

A biocidal product comprises of active ingredients which provide an effect on one or more target organisms relevant to the use being considered. At Arxada we use metagenomic DNA Analysis to assess how well proposed active ingredients work to inhibit the growth of target organisms that cause wood decay. Our goal is to provide the most efficacious wood preservatives on the market, that are more sustainable and have minimal impact on the environment, human and animal health.

For the metagenomic DNA Analysis, the Arxada research and development team use an Oxford Nanopore GridION sequencer to read DNA sequences one base at a time, as the DNA passes through a tiny hole, the ‘nanopore’. The resulting sequences are compared against the Arxada custom DNA database, which allows us to identify fungi, bacteria, archaea, viruses, and other organisms that are present in our samples.

The application of this technique allowed us to identify a highly effective combination of actives in the development of Tanasote S40, Arxada’s modern oil-based copper wood preservative alternative to Creosote. Tanasote S40 is the first wood preservative to make use of a new class of actives, SDHIs (Succinate Dehydrogenase Inhibitors) and incorporates Arxada’s own DDACarbonate quaternary ammonium compound.

LABORATORY AND FIELD TESTS

Once we have explored the performance of potential actives using metagenomic DNA Analysis, we then invest in testing to build the BPR efficacy package.

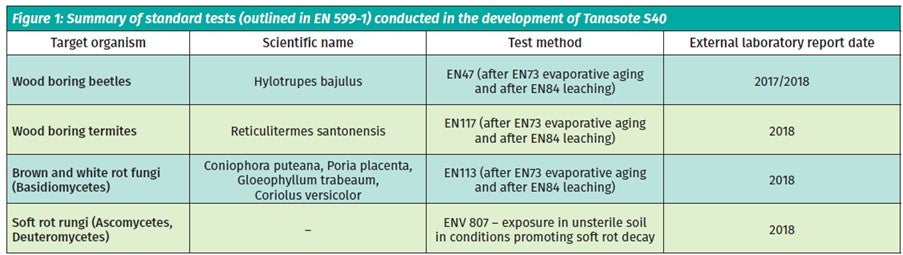

To bring any wood preservative system to market in Europe, they must be subjected to standard biological efficacy testing against decay fungi and wood destroying insects (outlined in EN 599-1). The table (Figure 2) shows the standard tests that were conducted in the development of Tanasote S40, which has received BPR authorisation across 23 countries including the UK and Ireland.

For the development of new wood preservatives, Arxada chooses to go beyond the standard test framework summarised in Figure 1. We invest in tests beyond what is required to ensure our wood preservatives are designed with optimised retentions of highly effective active substances to deliver long-service life. In the development of Tanasote S40, we engaged in additional laboratory fungal decay tests against nonstandard, very aggressive rogue fungi, such as Fibroporia (Antrodia) vaillantii, which has been known to cause significant mass-loss to competing products. Tanasote S40 controlled Fibroporia (Antrodia) vaillantii at the lowest concentration tested, well below the commercial retention. Fungal cellar tests were also used to stress the Tanasote S40-treated timber in accelerated groundcontact scenarios.

In addition to the non-standard fungal decay tests, our test formulations are installed in aggressive high humidity locations in Europe, North America, and Asia to compare their performance in ground contact applications with well known (now withdrawn) industrial preservatives such as CCA and Creosote. To bring the above to life, I again refer to Tanasote S40. In accordance with AWPA E7-15 stake testing, in these high humidity locations, Tanasote S40 continues to perform as well as high levels of CCA (>12 kg/m required in BS5589 for 40-year service life of softwoods) and industrial levels of Creosote. The performance of the global stake tests are assessed annually and, to date, Tanasote S40 continues to perform as well or better than industry standards.

MOVING TOWARDS COMMERCIALISATION

Once the research and development team are confident in the actives and the biocide formulation, we then work closely with our colleagues in Regulatory to help build the BPR efficacy package for authorisation. Our other key stakeholders are the manufacturing, commercial and sustainability teams.

We trial production on a small scale to ensure our micro-biological designs can be delivered in a way that work for the timber treaters (by bulk delivery or IBC). We also work with the commercial team and the wider sustainability team to look at Life Cycle Analysis and Environmental Product Declarations and prepare the necessary data for them to move these studies forward.

The world of chemists in wood preservation is an exciting one, full of challenges as the regulatory world of actives available becomes smaller. But we relish this challenge and strive to solve wood preservation challenges by enhancing sustainability with cleaner, greener solutions.

However, this does take time and the team at Arxada is already working on products that we will look to launch not only in the coming years, but through 2030 and beyond.