Two-layer wood-based composite with fireresistant cellulose-carbon core’ was the title of a research paper that created interest when it was presented at the International Panel Products Symposium in late 2023.

The multi-year research presents an interesting possible alternative to traditional methods of boosting the fire-resistance credentials of wood products.

Lead researcher Bartłomiej Mazela, of Poznan University of Life Sciences, Poland outlined the research project, which is financed by the National Centre for Research and Development as programme operator of the programme ‘applied research’ implemented under the Norwegian Financial Mechanism 2014-2021.

Prof Dr Bartłomiej Mazela outlined the several existing ways of producing a combined fire retardant and wood preservative treatment system.

One method is modifying an existing preservative, suitable for indoor or outdoor applications, by adding a fire retardant. This process is focused on the impregnation of conventional preservatives to raise fire retardancy.

Another method is modifying wood with inorganic compounds to form wood-inorganic composites.

The rapid rise in popularity of wooden buildings and the increasing orientation of producers and consumers to pro-ecological solutions, means it is necessary to increase the fire resistance of wood and wood-based materials.

Many different methods of flame-retardant treatment of wood and wood-based materials exist in the building industry, particularly in wood construction.

One method is via surface coating. The second and most effective application is soaking or pressure treatment of plywood, while the third process is the addition of fire retardants to resin.

These methods reduce the flammability of wood and wood-based products by delaying the moment of material ignition, reducing the speed of surface spread of flames and reducing the intensity of easily flammable burning materials.

The most popular method of fire protection for a wood-based panel on the market is a coating.

The advantages are as follows:

- Easy application

- The most popular fire protection solution on the market

- Improving the fire classification of woodbased materials to class B

- Transparent coating is available

Disadvantages:

- Several layers of coating are required

- Expensive

- Unstable in outdoor use (leachable)

- Not suitable for materials which are thinner than 12mm

- High density product (>700kg/m3)

In terms of fire protection through deep impregnation – the advantages are that it is not expensive, it is well-known on the market, it improves the fire classification of wood to class B and it does not change the colour and texture of the wood.

But the disadvantages include the fact that expensive equipment is required, it can be unstable in outdoor use (leachable); not suitable for materials which are thinner than 12mm and it is a high density product (>700kg/m3).

An alternative to the use of traditional fire retardants are retardants that change the flammability of wood and wood-based material by manipulating the condensed phase chemistry. Additives promoting charcoal forming during wood combustion are very effective fire retardants.

Intumescent EG is a low-density carbon material with unique properties. It has a developed specific surface, stability to aggressive media and low thermal conductivity. EG’s expansion process starts when a temperature is higher than 220°C.

In this approach, the wood coated or encrusted with graphite starts to be protected via foam and extra charcoal formation when the temperature is lower than 260°C, which means the temperature is below the temperature of the ignition of wood.

Another solution is an expanded graphite (expandable graphite) application for flame retardant. In particular, its use as a flame retardant for materials and /or products consisting of or containing woodfibres, cellulose fibres, wood powder, cellulose powder, wood granules, cellulose granules and /or polyolefin-based materials. This is deposited in materials or products to reduce flammability.

The invention also relates to an agent where expanded graphite is used alone or in combination with a mixture of boric acid/ borax/alkaline salt.

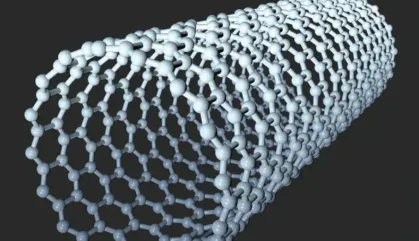

One of the promising nanomaterials as a source of additional carbon is carbon nanotubes (CNTs). CNTs are a popular addition to polymer composites to enhance mechanical properties and fire resistance.

CNTs dispersed in a matrix of polystyrene and polymethylmethacrylate can be used as a flame retardant.

RESEARCH AND TESTING

The research aims to develop thin two-layer composite materials (max 5mm thickness) showing the potential for the classification Bs1,d0, according to EN 13501-1.

The scope of the work includes production of a two-layer composite. The inner layer of the composite consists of a cellulose carrier containing expanded graphite and carbon nanotubes and the other layers are pine veneers.

To produce the two-layers composite, cellulosic fibres were immersed in de-ionised water for 24hrs for improved defibrillation during cellulose sheet production.

Graphite and carbon nanotubes were added directly before sheet production into the water-stage cellulose fibres (5% concentration). The manufacturing process included these steps: stirring adhesives and cellulosic fibres, floating of fibres, water removal by vacuum and vacuum drying of the final product.

The exterior veneer was glued by starch/ acetic glue in a hot press.

The starch/acetic glue was produced as follows: 10g of potato starch was weighed and then 20ml of water was added to it with intensive stirring. A beaker with 80ml water was placed in a water bath and heated to 80°C. After reaching the desired water temperature, the starch suspension in water was added and intensively stirred for about 1min until a dense mass was obtained. Then 10ml of acetic acid was added and stirred for about 1min. A dense mass with the consistency of a gel was obtained.

The glue was applied with a brush. The produced cellulose sheets were glued using starch/acetic glue applied to the surface of the modified material and a layer of veneer was added. The pre-glued material was conditioned at room temperature under load for 1hr and then pressed at 85°C and 1.5MPa pressing pressure also for 1hr.

For the above variants, pine veneer was used with a thickness of 0.64mm and a moisture content of 4.48%, with 10x10cm dimensions.

The following variants were selected for the testing:

- Reference samples – two layers of veneer glued without a middle cellulose layer

- Control samples – two layers of veneer glued with an intermediate layer made of cellulose sheet

- Composite samples – two layers of veneer glue with a middle layer made of a sheet of carbon-nanotubes/graphite modified cellulose in ration 1:1:1

FIRE BEHAVIOUR AND RESULTS

An ISO 5660-1 analysis was performed at a heat flux of 50kW/m2 with a spark igniter used as a preliminary test for fire certification. Tests were carried out using the ISO 5660 method on samples with 100x1200mm dimensions and different thicknesses. The sample was positioned 25mm from the edge of the cone. The tests were conducted at an ambient temperature of 17°C, barometric pressure of 1001hPa, and air humidity of 39%.

The test duration was 1,200sec.

Variants selected for the test were: 1.73mm thick for the reference sample; 1.82mm thick for the control sample; and 3.68mm thick for composite samples.

The lowest heat release rate (HRR) was observed for the composite sample, which amounts to 219kW/m2. This value is reached after 30sec of the test.

This is a significant improvement in the flammability parameters of the composite and the HRR is reduced by around 30% compared to the reference and control samples.

One of the crucial parameters is the maximum average rate of heat emission (MAHRE). After 600sec for the composite sample this is 89kW/m2. These parameters are a reduction by 41% and 45% compared to the reference and control samples.

Modifying the cellulose with carbons of inorganic origin (EG and CNT) did not affect the ignition time of the sample. Ignition was observed within 16-18sec of starting the test.

Notably, the control and reference samples were extinguished after about 100sec, while the composite burned twice as long. Therefore, the kinetics of combustion changes, confirmed by the analysis of the gases emitted during the test.

The control and reference samples emitted significantly more CO2 than the composite. On the other hand, more CO2 is released during the combustion of the composites. The smoke emission of the composite is significantly lower than the control and reference samples.

CONCLUSIONS

Developing a two-layer composite material with a thickness of about 4.5mm has increased fire resistance compared to the reference and control materials. The reduction of the total smoke production and the total smoke emission (almost four times) proves the high ability of the material with the participation of EG/CNT to retain carbon in the structure. This fact significantly impacts the development of environmentally friendly materials and their classification.

The HRR and MAHRE performance also allows the assumption that this material may be classified as a class C according to EN 13501-1. It is most likely necessary to apply an additional coating to increase the fire resistance of a thin composite to the B classification.